SHILP was started in 1995 by a first generation entrepreneur Jayesh Patel. Mr. Jayesh Patel is in the field of refractory business since 12 years. He started the unit as small scale industries with Refractory cassette box (sagger) of 14500 Nos. per month. He Was Technocrat with his confidences & development skill.

We under take all types of specially product development fire bricks, fire tiles, kiln furniture, Castable & mortar, any refractory shape & different requirement of customers. We produce high Alumina Refractories for forging, steel, glass, chemical, cement & power plants.

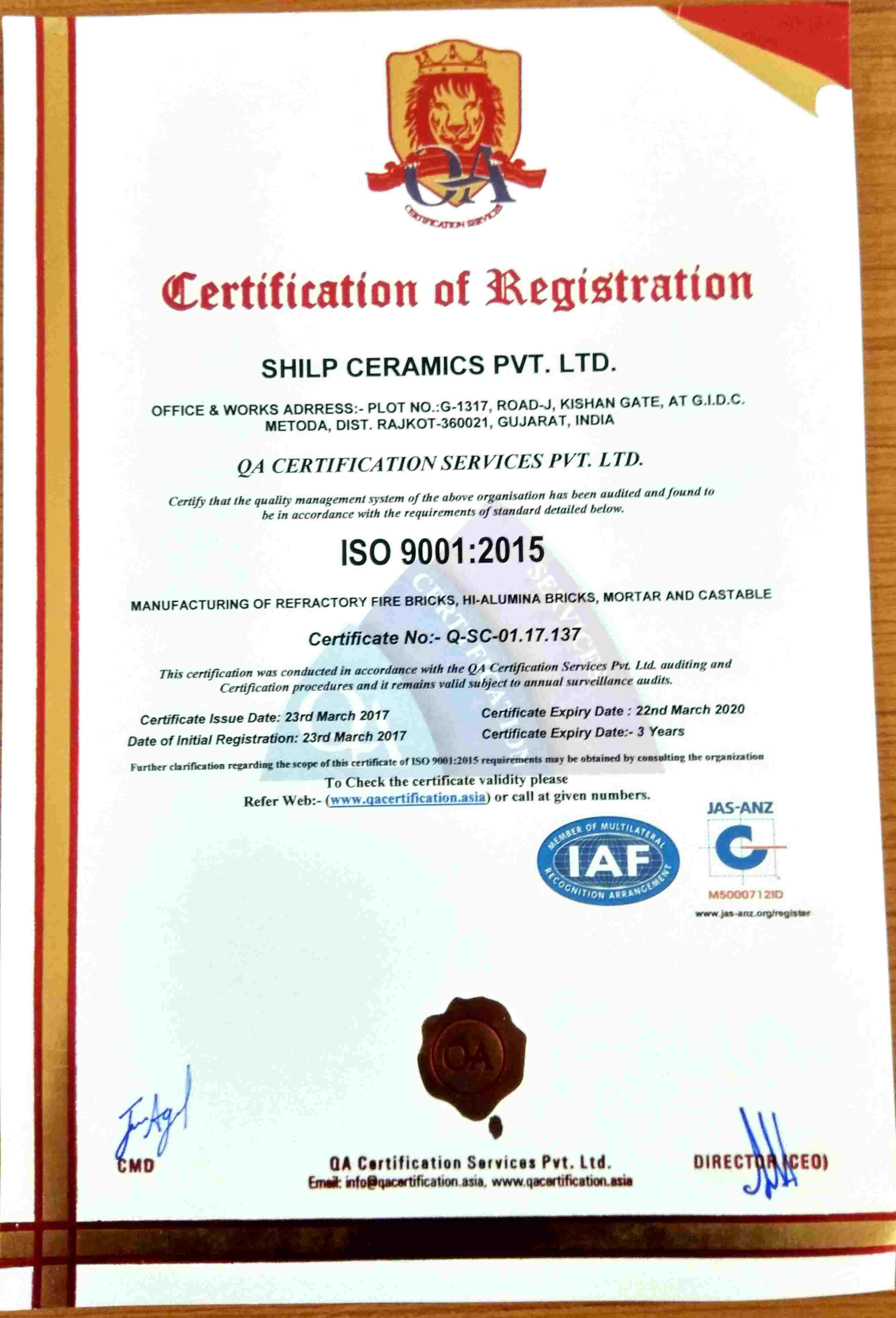

QUALITY ASSURANCE

We use best quality materials in Refractory production. Working in accordance with the operations, the Quality Assurance Department is diligently involved in the entire process of a thorough check of the incoming raw material to the in-process checks to the final testing and inspection. All procedures like grinding, mixing, blending and firing of the kiln temperature are closely monitored and studied. Customers are delivered the finished goods after their rigid scrutiny, ensuring zero defect output. So, we are gives best services to our customers.

MISSION

“SHILP” was manufacturer of high alumina fire bricks & Othe refractory shape. Shilp Ceramic is dedicated to providing our customers with a superior level of service. We try to give maximum level of satisfaction to the customer’s all kind of inquiries like ordering small, medium or large quantity. Our prices are affordable to our customers. In the business of heat management our products offer immense value to our customers. We help them by minimizing plant shutdowns, maintenance cost & heat losses and maximizing their operational efficiency, productivity and earnings and total commitment to best quality. “QUALITY PRODUCT IS OUR MISSION”

PHILOSOPHY

Our good man-management activity as a customer’s satisfaction. Quality has played an important role in every surface of our business activity. The basic objective of the company's team management is to get and supply only those quality products which can get the customer's necessary & essential requirement as per international standards of performance, quality, & reliability. SHILP always believes that the growth in its business status and stature depend slowly upon the economy and efficiency of operations that its customers derive from performance of the products, as well as the service support extended to them.

DIRECTORS MESSAGE:

"I've worked too hard and too long to let anything stand in the way of my goals. I will not let my teammates down and I will not let myself down."

Mr. Jayesh Patel

Mr. Jayesh Patel "In motivating people, you've got to engage their minds and their hearts. I motivate people, I hope, by example - and perhaps by excitement, by having productive ideas to make others feel involved."

Mr. Shailesh Patel

Mr. Shailesh Patel "Determine never to be idle. No person will have occasion to complain of the want of time who never loses any. It is wonderful how much may be done if we are always doing."

Mr. Vipul Patel

Mr. Vipul Patel

Size :-

230X115X75mm STD, S/A & E/A

230X115X25mm

230X115X38mm

230X115X50mm

230X115X65mm

230X150X38mm

230X150X50mm

230X150X75mm STD, S/A & E/A

230X150X100mm

230X200X100mm

300X150X75mm

Mortars are used in joining materials for laying refractory bricks. Our company manufactures and supplies wide range of Refractory Mortar. These mortars are used as jointing materials for various construction activities. We can make available this Refractory Mortar in different specifications as per buyer’s requirements. Buyers can make retail as well as bulk orders. We promise to deliver them in given time period efficiently.

SHILP HEAT - A

SHILP HEAT - K

SHILP HEAT - C

SHILP COILCOAT - A

SHILP COILCOAT - K

Size :-

230X115X75mm STD, S/A & E/A

230X115X25mm

230X115X38mm

230X115X50mm

230X115X65mm

230X150X38mm

230X150X50mm

230X150X75mm STD, S/A & E/A

230X150X100mm

230X200X100mm

300X150X75mm

Size :-

230X115X75mm STD, S/A & E/A

230X115X25mm

230X115X38mm

230X115X50mm

230X115X65mm

230X150X38mm

230X150X50mm

230X150X75mm STD, S/A & E/A

230X150X100mm

230X200X100mm

300X150X75mm

Size :-

230X115X75mm STD, S/A & E/A

230X115X25mm

230X115X38mm

230X115X50mm

230X115X65mm

230X150X38mm

230X150X50mm

230X150X75mm STD, S/A & E/A

230X150X100mm

230X200X100mm

300X150X75mm

SHILP SET- 50 is an additive for modifying cement mortar /concrete which improves the properties of cementitious compositions. It improves bond strength, mechanical properties & abrasion resistance of cement concrete / mortar. Thin sections dry rapidly and exhibit good adhesion to old concrete & masonry, brick, wood, metals & many other surfaces.

Shilp aluminate cements are for use in refractories designed for service up to 1800°C (3300°F):

SHILP CRETE SUPER

SHILP CRETE NORMAL

SHILP CRETE SPECIAL

SHILP THERMO CRETE SUPER

SHILP CRETE- E

Size :-

230X115X75mm STD, S/A & E/A

230X115X25mm

230X115X38mm

230X115X50mm

230X115X65mm

230X150X38mm

230X150X50mm

230X150X75mm STD, S/A & E/A

230X150X100mm

230X200X100mm

300X150X75mm

SHILP SET - 70 mortar is a special mortar containing high percentage of alumina. This mortar can withstand very high temperatures of up to 1600 degree Celsius. This product is formulated to be applied for lining of high alumina bricks.

Insulating castable is designed to display low density and low thermal conductivity so as to keep heat energy and to reduce fossil energy consumption.

SHILP LYT- 11

SHILP LYT - HT

.jpg)

6”X6”X6”

9”X9”X9” (SIMPLE & W.T.)

9”X9”X13”

10”X10”X10” (“U” SHAPE)

12”X12”X12” (SIMPLE & “U” SHAPE)

14”X14”X14”

15”X15”X15”

16”X16”X16”

18”X18”X18”

& Also Avilable as per your Requirement Size........

9”X9”X3”

12”X12”X1”

12”X12”X3”

15”X12”X3”

18”X9”X3”

18”X9”X4.5”

18”X9”X6”

18”X12”X3”

18”X12”X4.5”

18”X12”X6”

18”X12”X12”

18”X18”X3”

24”X6”X6”

24”X12”X3”

24”X12”X4.5”

24”X12”X6”

24”X12”X8”

24”X12”X12”

24”X18”X3”

24”X18”X6”

24”X18”X12”

24”X24”X3”

24”X24”X6”

36”X12”X3”

36”X12”X12”

36”X18”X12”

& Also Avilable as per your Requirement Size........

NOZZEL

WELL BLOCK

SLIVE

HALF ROUND

ARCH BLOCK

SKEW BLOCK

ETC....

& Also Avilable as per your Requirement Size........

We have a team of experienced and well trained engineers for all kind of Refractories and Anti-corrosive applications. We undertake total projects for Refractories Application and also emergency repairs, shut-down maintenance etc.

Life is sacred. Celebrate life. Care for others and share whatever you have with those less fortunate than you. Broaden your vision, for the whole world belongs to you.

- Rolling Mills & Forging Furnace

- Iron & Steel Industries

- Gas & Coke work

- Engineers Industries

- Glass Industries

- Fertilizer & Chemical Industries

- Sponge Iron, Iron Palletizing furnaces

- Power Plants

- Silicate Industries

- Petro Chemical & Oil refineries

- Sugar Industries

- Metal Powder furnaces

- Special Purpose Furnace

- Ferrous & Non-ferrous Foundries

- Industrial Furnace/Boiler

- Railways

- Ceramic Industries

- Paper Industries

- Cement & Lime Industries

- Heat Treatment throughout India

SHILP Refractories’ Refractory Research and Development Lab has produced many quality materials. Our lab is staffed with expert ceramic engineers and material scientists. The lab is responsible for new product ideas and ways of improving existing products. We can section and examine your spent refractory to determine causes of failure. Our Failure analysis can lead to a better suited material recommendation for your challenging refractory needs. We have developed mixes custom tailored to our customer’s specific applications. These new mixes extend the service life of the precast shapes they are used in. Extended service life leads to more production time with reduced down-times from outages. This leads to money saved – and more product manufactured.

Our Refractory Research and Development lab can offer suggestions on how to increase service life of an existing material or part through material selection; however, we know that not every problem can be solved with an existing product. Our lab can custom design your material to alleviate your failure method. We can reformulate castables to change everything – from chemistry, to rheology, to grain size.

Our lab also ensures the consistency of our castable products and precast pieces through a comprehensive QC program from raw materials qualification to finished castables testing. Contact us today with your R&D needs.

Contact us today with your R&D needs.

For More Details & Information Send us Inquiry

SHILP CERAMICS PRIVATE LIMITED.

![]() : Plot No. G/1317, Phase No II,

: Plot No. G/1317, Phase No II,

B/h. Gujarat Gas, G.I.D.C METODA

Dist. Rajkot - 360021 (Gujarat) India.

![]() : + 91-2827-287220

: + 91-2827-287220

![]() : + 91-2827- 287742

: + 91-2827- 287742

![]() : shilpceramics@yahoo.co.in

: shilpceramics@yahoo.co.in

![]() : www.shilpceramics.com

: www.shilpceramics.com

SHILP REFRACTORIES PRIVATE LIMITED.

![]() : SURVEY NO 156/157/1/2,AT RANGPAR

: SURVEY NO 156/157/1/2,AT RANGPAR

TA. WAKANER,

DIST. MORBI- 363621 (Gujarat) India.

![]() : info@shilpceramics.com

: info@shilpceramics.com